|

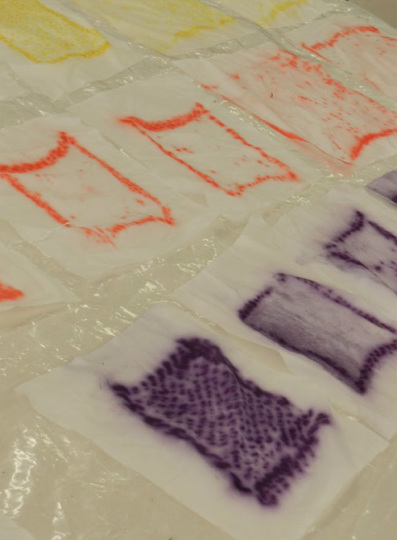

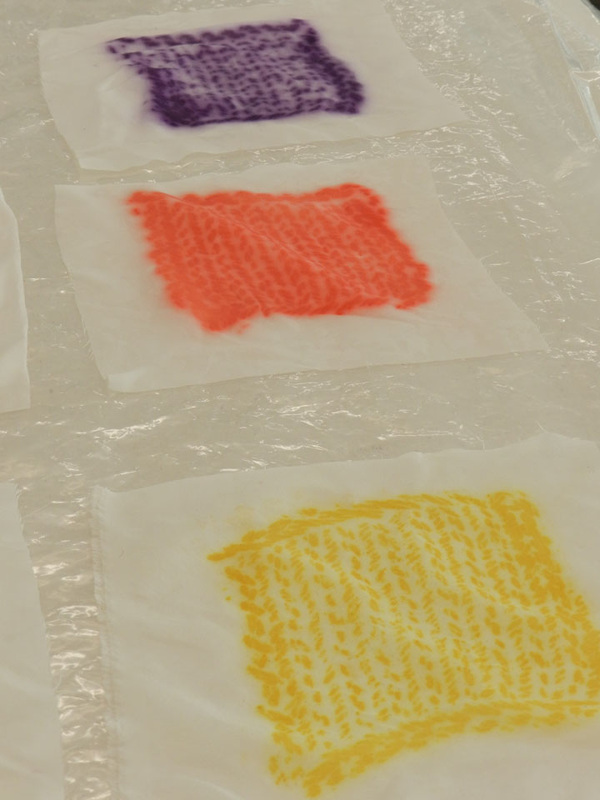

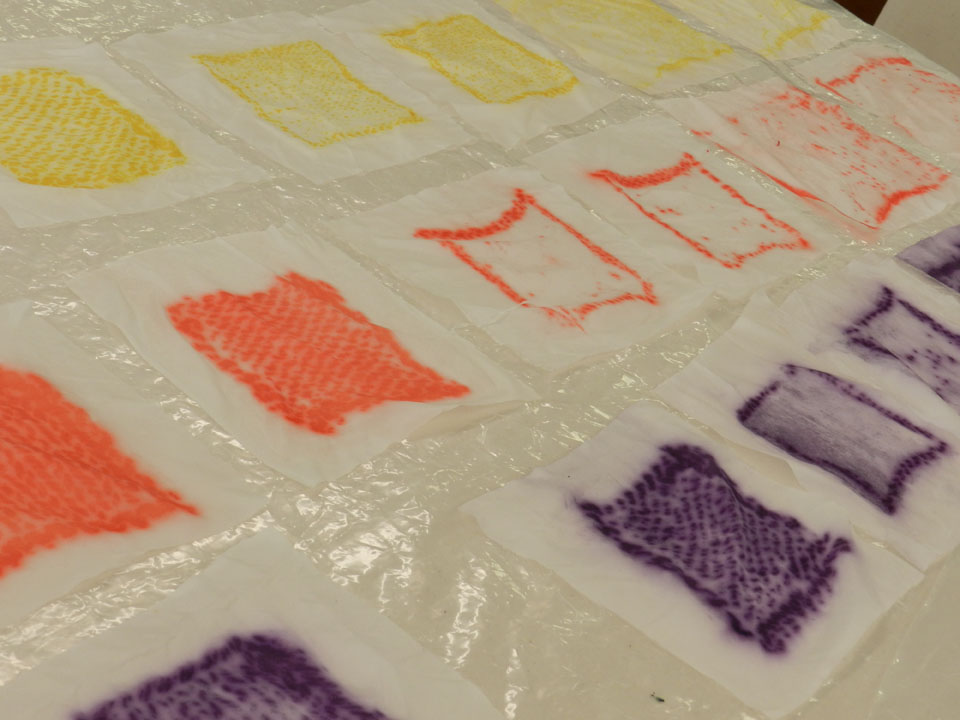

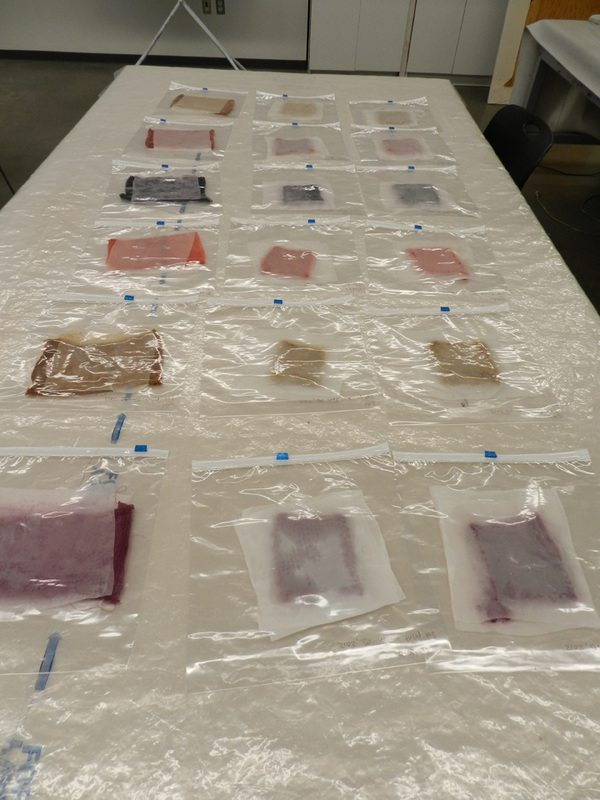

I began solid prints #2 today and I think I'll leave them even longer this time, perhaps 9 days. I put them in extra wet this time and arranged them so all the fine swatches were placed on one side of the table and the thick ones on the other. I think having the thick ones beside the thin ones didn't allow for enough pressure on the thin ones, creating mostly an outline of the thinner ones.

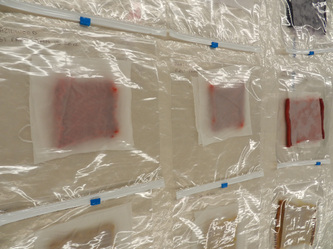

I also think the madder and cochineal may not have many more prints in them, if even a second one. We'll see next week.

0 Comments

today I took the first prints out and they look great. I'm really happy with the results. All the details to come in another post.

Today I did print #1. The swatches are underneath two print boards. I'll leave them there for one week.

taking the fibres out of the dye pots I squeezed the fibre. Then I sandwiched each swatch between two pieces of 6"x6" habotai silk. I left the plastic bags half open to allow a little of air into the bags. Once they were all inside the marked bags i sandwiched them with another print board (soft side down). Another print board was placed on-top of it print side up so students can still use the printing table.

I'd like to somehow calculate the weight of it so I can add the info to my notes. from left to right: Cochineal, brazilwood, osage, madder, fustic, logwood

1tsp cochineal ground with pestle and mortar until fine powder, 1. Boiled for 45 minutes in 4 litres of H2O 2. Added fibres (leaving dye stuff bag in) 3. let simmer for 1.5 hrs 4. Let cool and sit for 24 hours.

1.made stock solution using 4 cups of H2O and 2TBP Brazilwood. Boiled for 45 min. 2.Emptied contents, added 4 cup of water to used brazilwood, boiled for 45 min. 3. Repeated step 2. 4. I used all 12 cups of stock solution for the yarn and swatches. 5. Added fibres and let simmer for 1.5 hrs 6. Let cool and sit for 24 hours.

1/4 cup osage sawdust 1. Boiled for 45 minutes in 4 litres of H2O 2. Added fibres (leaving osage bag in) 3. let simmer for 1.5 hrs 4. Let cool and sit for 24 hours.

1/4 cup madder powder 1. Boiled for 45 minutes in 4 litres of H2O 2. Added fibres (leaving madder bag in) 3. let simmer for 1.5 hrs 4. Let cool and sit for 24 hours.

1 TBS fustic extract 1. Dissolved fustic concentrate in warm water 2. Added fibres and let simmer for 1.5 hrs 3. Let cool and sit for 24 hours.

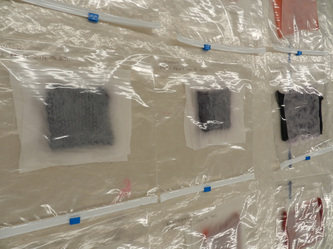

1/2 cup logwood chips

1. Boiled for 45 minutes in 4 litres of H2O 2. Added fibres (leaving logwood bag in) 3. let simmer for 1.5 hrs 4. Let cool and sit for 24 hours. * all of the fibre photos are of the fibres, still wet and without any rinsing. I will use these yarns for the multicolour samples. Concordia unknown wool (will find out)

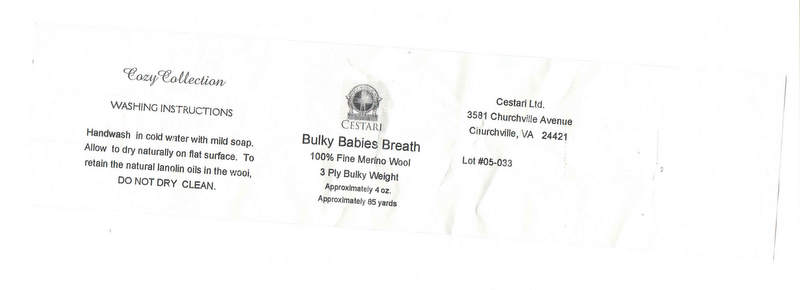

knit on metal machine in fibres room (blue) on gauge 3. Using the Singer LK 100 knitting machine on gauge 3.

Yarn info: 100% wool. woolen spun. findings: 13 stitches and 26 rows = 3" X 4" unblocked 17 stitches and 26 rows = 4" X 4" unblocked embroidery is something I considered using and then kind of forgot about. I like the idea of have control over the flow of the stitches like in this piece, and love the idea of many french knots. I'll have to do some samples and see what happens.

|

Links to other pages

_Independent Study- calendar Proposal Categories in notes section

All

Archives |